On an industrial level, there are several coating methods competing with one other. Their application depends on the requirements for the final product considering material properties, feasibility, and cost efficiency.

Benefits of EBPVD

Of all those methods, electron beam assisted physical vapor deposition, or in short EBPVD, plays a very special role. On the one hand, it enables a much higher evaporation rate compared to cheaper thermal evaporation methods. And on the other hand, materials can be used that can only be evaporated in vacuum and with the high energy density that is a characteristic of electron beams. Furthermore, so called sublimation methods, for instance the one of silicon dioxide for barrier coatings on polymer films in the packaging industry, can be done using electron beam technology.

Fields of application

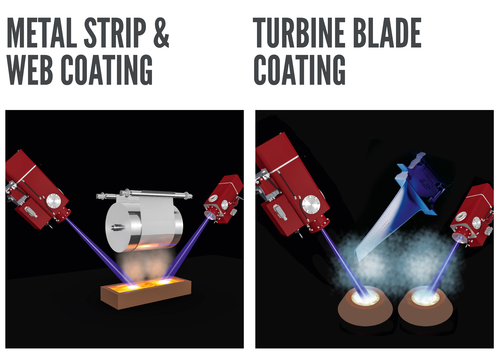

Apart from polymer films, there are other substrates that can be coated with relatively dense layers such as metal strip, glass, or turbine blades. For those applications, EBPVD can also be combined with other methods such as plasma spray coating. This can be useful to meet the complex material properties required by the aerospace industry. In the simplest case, the material to be evaporated can act as fa point source where an electron beam melts a material in a crucible. If dimensioned correctly, the vapor cloud that is created above enables a homogeneous layer deposition on the target material. These point sources can also be combined in such a way that the resulting vapor clouds overlap and enable a homogeneous layer deposition across a larger substrate width. The image shows this on the example of a turbine blade.

Adjustable electron beams for more precision

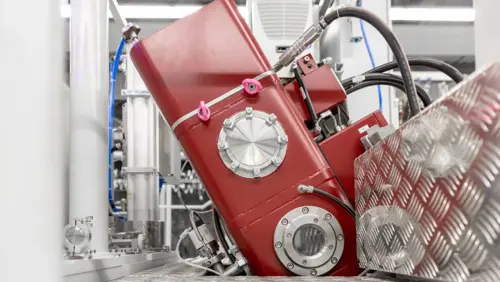

If the requirements for controlling the layer thickness are higher, this static process can be replaced by an adjustable electron beam. This is only possible because electron beams can be easily and precisely controlled. The electron beam can be guided across the whole width of the crucible at high speed. The intensity of the electron beam is controlled by means of a layer thickness measuring system covering the same width. To increase the width of the coating area, several electron beam guns can be used across the whole width as it is shown in the picture.

Summing up, we can say that the use of reliable electron beam systems in physical vapor deposition facilitated the implementation of many coating methods and their cost-efficient application in the first place. Furthermore, the combination of EBPVD with other coating methods enables a wide a promising range of applications.

If you would like to know more about this technology, please click here.