In our previous articles, we have shown that sputtering has developed into an indispensable coating method and has matured technologically due to continuous evolution. The maturity and the versatility of this technology make it an interesting option for many new fields of application. But with this potential come new challenges that need to be addressed and that cannot be met by just optimizing the hardware.

Microelectronics as a driving force

Once again, microelectronics and computer technology were instrumental for the next evolutionary step – even in two ways: First of all, it was the sputtering technology that enabled the production of affordable microelectronic components in high quality in the first place in the 1970s. On top of that, sputtering helped create microelectronic products that in return helped improve this coating technology.

How the data is gathered

For example, there are several sensors built into modern coating systems today that can process comprehensive product and process data, in part even in real time. This data can be evaluated by ever-evolving high-performance computer technology which contributes to optimizing the coating process.

Furthermore, most of the components used in a coating system have their own computerized control system. And there is a variety of options for controlling and analyzing the generators of the magnetrons. These options go far beyond the mere displaying of electric current, voltage, and performance. Even vacuum pumps, pressure sensors and gas flow controllers can provide a multitude of data beyond measurements and their condition if they are connected via bus systems.

Powerful spectrometers, which are linked directly to the sputtering process through optical cables, or electric sensors in the process area provide real-time information about the density of the plasma and the local composition of the gas in the plasma. These are valuable pieces of information for controlling the coating process. Optical sensors and resistance measuring devices that are integrated in every magnetron lid provide exact information about the properties of each individual layer. Therefore, they help visualize the result of adapting certain process parameters to evaluate the success of those measures.

New applications, new challenges – but loads of data

All these factors are important prerequisites for meeting the ever-increasing requirements for layer thickness homogeneity and layer properties that are necessary for new applications. Furthermore, these capabilities open new ways for applying novel, interesting coating materials such as aluminum oxide, the deposition of which has been too difficult and unstable before.

By combining these capabilities with advanced equipment technology, we can reach the next level of quality. In optics and architectural glass coating, for instance, it is increasingly required to achieve more complex layer stacks and layer thickness homogeneities with lower manpower.

In addition, new sputter materials are being used and the number of products that are processed per machine is increasing. This makes it necessary to shorten set-up and ramp-up times. Other driving forces are the striving for more sustainability and the cost pressure regarding process and operation. Thus, it is worthwhile to focus on aspects such as target utilization, energy-efficient production, and temperature management.

Making use of all the data

The availability of data alone, however, does not help with meeting the high requirements. But the crucial elements are the analysis software and the algorithms the data analysis is based on and which can make real-time decisions.

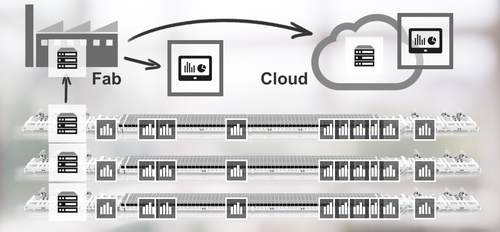

As one of the first in the industry, VON ARDENNE has developed a modular software suite for data analysis and process control called VA INDIGO. It is based on the vast know-how and experience gained during a large number of machine installations and ramp-ups of coating processes. It makes it easier for customers to ramp up new processes when changing to a new product but also reduces the maintenance and service times for the equipment.

Nevertheless, there is still a large amount of data gained from commissioning and operating coating systems that is still unused. The potential this offers is huge once this treasure of data is systematically recorded and analyzed. And this analysis is getting easier and easier thanks to faster computing power and AI-based methods to be available for the production process or process modulation.