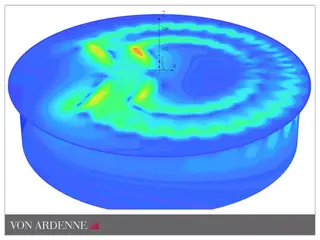

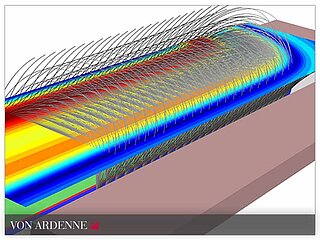

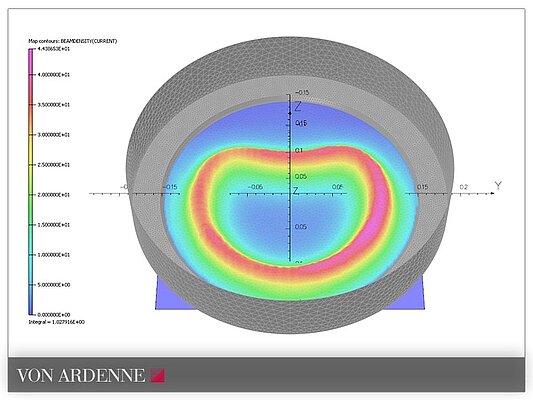

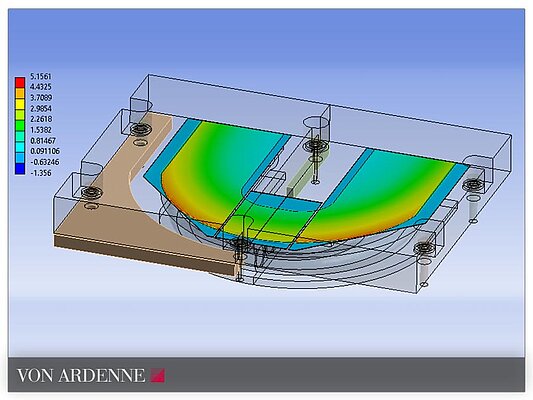

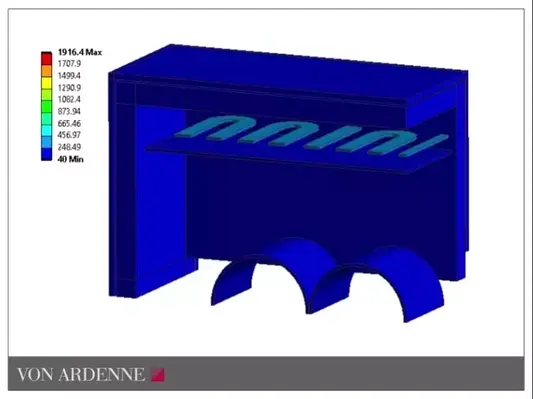

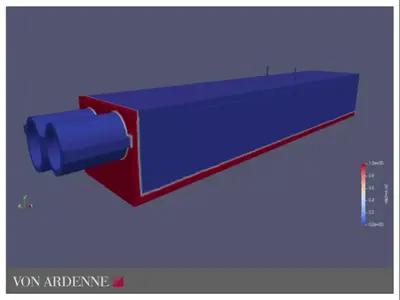

Electromagnetics Simulations

What?

Modeling of

- Electric coils

- Permanent magnets

- Ferromagnetic materials with non-linear B-H curves and hystereses

- DC and AC processes

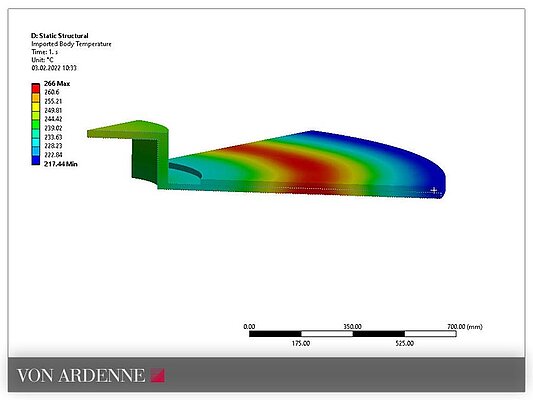

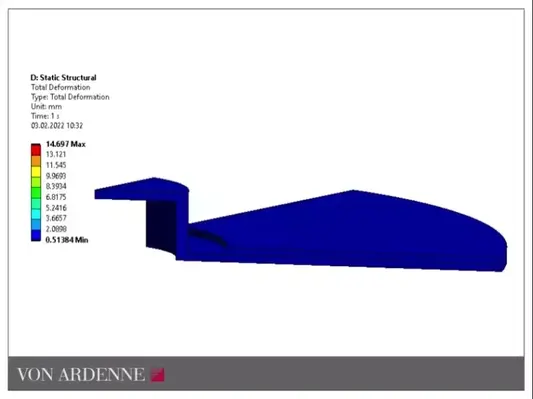

- Electrothermic coupling

- Electromagnetic coupling

With What?

- Ansys

- Comsol

- CST/Opera

What For?

- Electric and magnetic fields

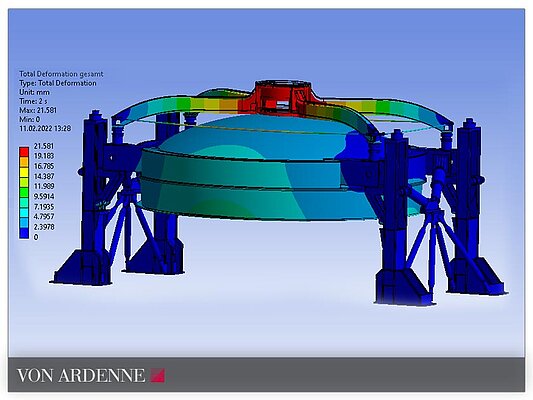

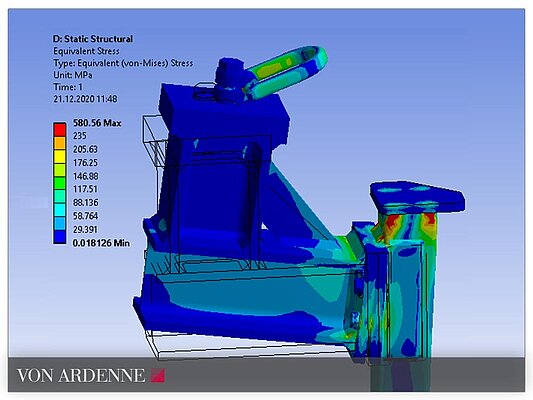

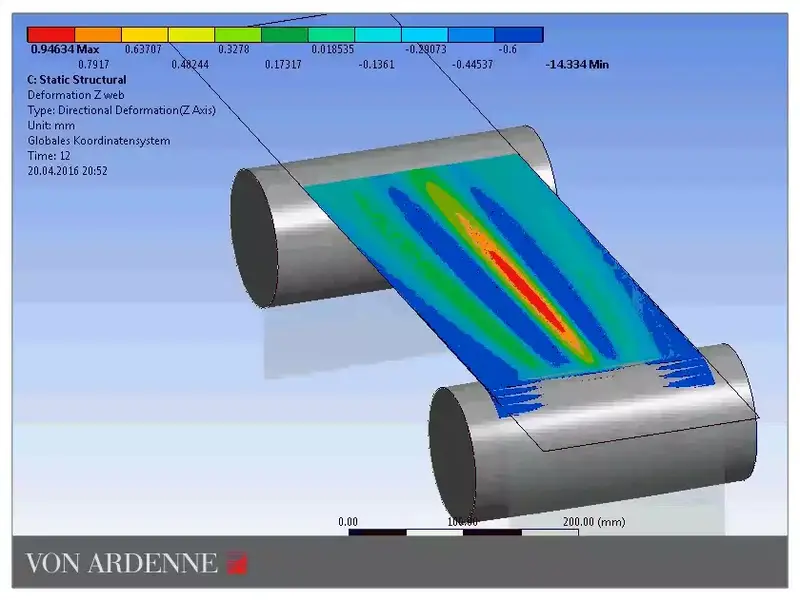

- Thermally induced deformation and stress

- Forces and torques from electromagnetic fields

- Skin effects and motion-induced eddy currents

- Magnetization of materials

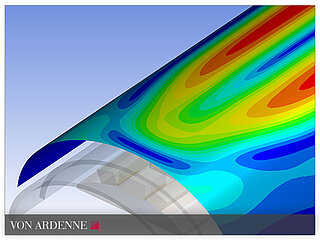

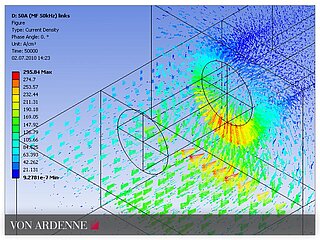

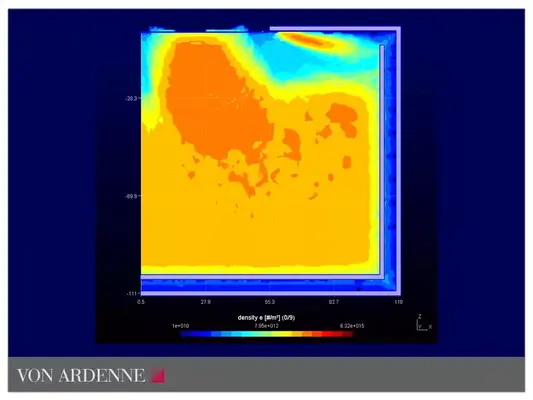

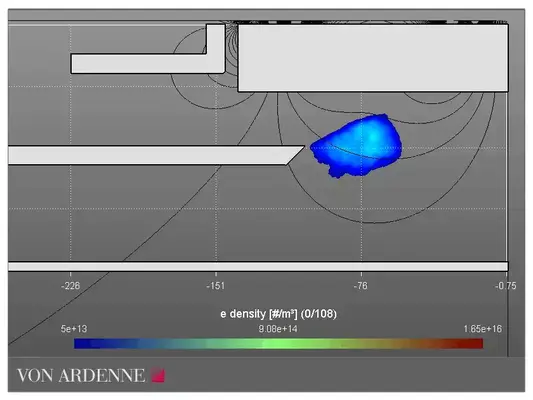

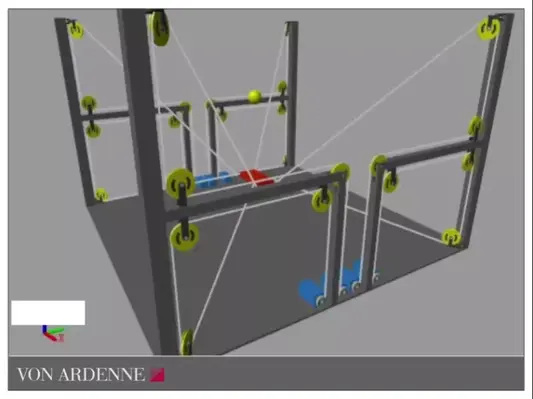

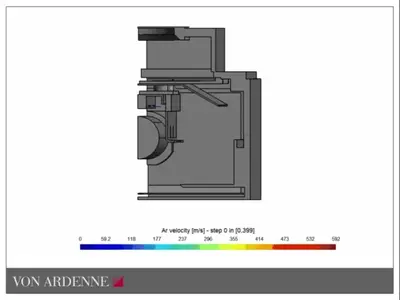

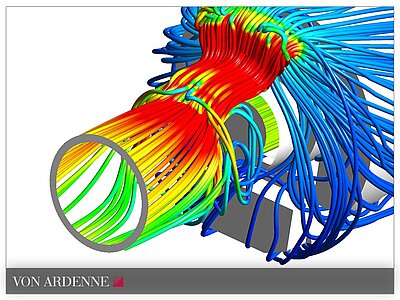

PLASMA SIMULATION

What?

- Simulation of charge carriers (ions and electrons) under the influence of electric and magnetic fields

- Development of low-pressure plasma in space

With What?

- PICMC

- Opera

What For?

- Influence of chamber geometry and orifices as well as eddy currents on plasma development

- Course of an electron beam under the influence of the magnetic field

- Intensity and distribution of back-scattered electrons of the electron beam

- Optimization of sputter and etch processes